Difference between revisions of "INDU-RS"

(→Software Setup Guide) |

(→Software Setup Guide) |

||

| Line 118: | Line 118: | ||

=Software Setup Guide= | =Software Setup Guide= | ||

| − | In general the RE/DE input requires high level while transmitting data and low level while receiving data. Whereas the standard RTS signal of UART remain low while transmitting data and high while receiving a data. UARTs can be put in RS-485 mode, which will automatically handles RE/DE signal using its RTS pin by | + | In general the RE/DE input requires high level while transmitting data and low level while receiving data. Whereas the standard RTS signal of UART remain low while transmitting data and high while receiving a data. UARTs can be put in RS-485 mode, which will automatically handles RE/DE signal using its RTS pin by using hardware inversion for correcting the default RTS nature. But the built in UARTs of AM335x series lack this hardware inversion capability for generating correct RE/DE signal. So while developing the RS485 application, there was need of software inversion for generating correct RE/DE signal while transmitting and receiving the data. |

In INDU-RS3HD and INDU-RS3HD-DC15W capes, Yantrr has added the hardware inversion capability which will generate correct RE/DE signal using default RTS pin in RS-485 mode without any need of software inversion in an application. | In INDU-RS3HD and INDU-RS3HD-DC15W capes, Yantrr has added the hardware inversion capability which will generate correct RE/DE signal using default RTS pin in RS-485 mode without any need of software inversion in an application. | ||

Revision as of 05:44, 14 March 2017

Contents

[hide]Overview

Yantrr INDU-RS series of capes provide the capability of interfacing with sensors and instruments using RS232/422/485. These capes are designed to industrial grade I/O interface standards assuring reliable operation and protection in extreme operating environments. The electronics on the capes has been tested to be in compliance with strict EU standards for radiated and conducted emissions.

Utilizing Modbus protocol, these capes can be used to transform VIBE/VIBE2 IoT platform into powerful SCADA & process control systems. INDU-RS capes are also fully compatible with BeagleBone CPU platform.

Quick Start Guide

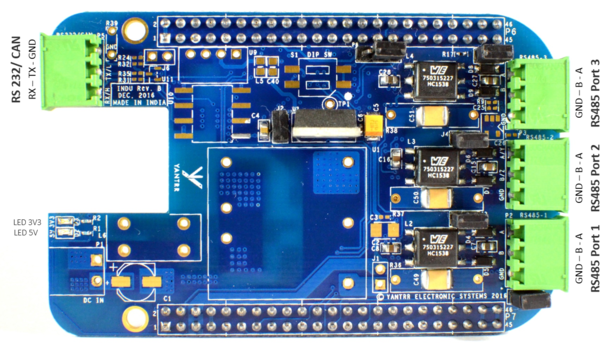

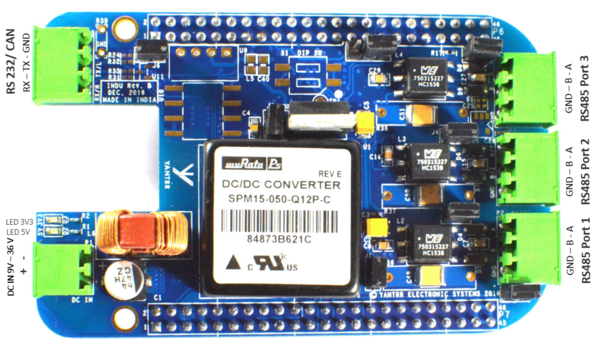

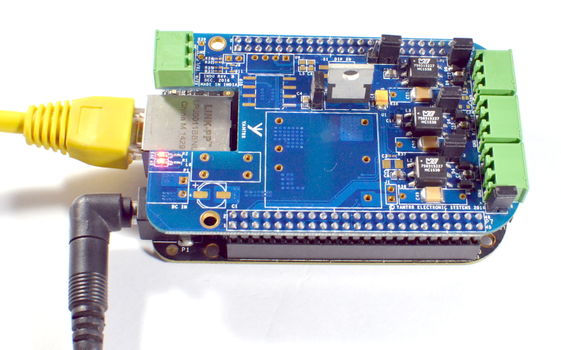

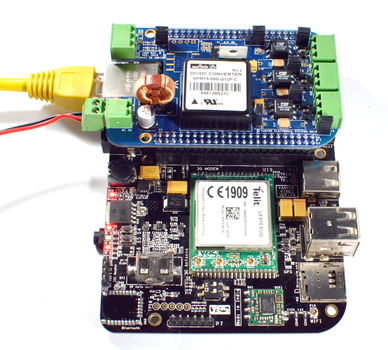

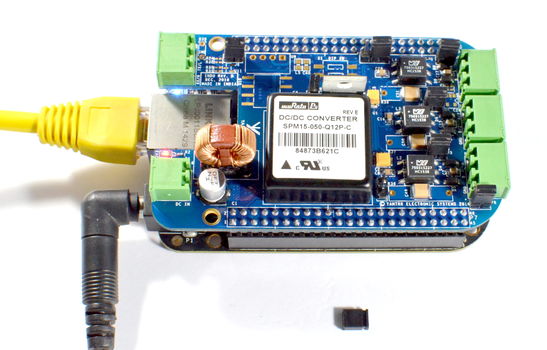

Following sections gives details of board connectors, pin configuration and various jumpers on INDU-RS3HD, INDU-RS3HD-DC15W boards.

Board Connectors Layout

| INDU-RS3HD | INDU-RS3HD-DC15W |

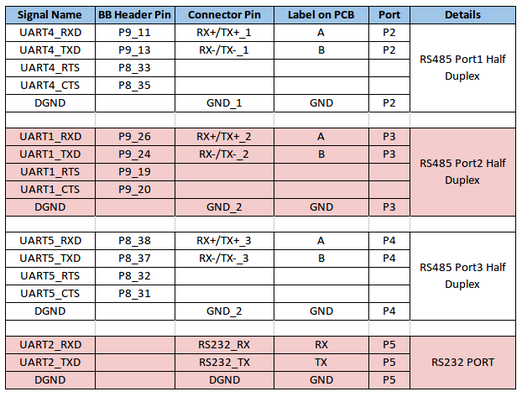

Pin Connections

Note: INDU-RS485 Headers P6 & P7 correspond to Beaglebone Black [BB] Header P8 & P9 respectively.

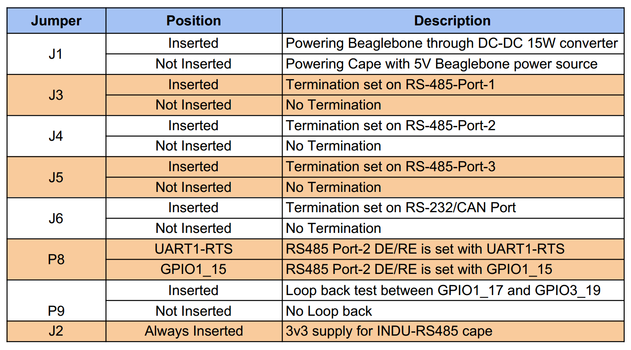

Jumper Details

Getting Started

Setting up the system

- Mount the INDU-RS cape on Beaglebone Black or Yantrr's VIBE/VIBE2 platform carefully.

- Ensure all the jumpers are in place according to your application use.

- Now power up the full setup

- Note: Before powering up ensure correct software image is loaded in Beaglebone black or VIBE/VIBE2

- For INDU-RS3HD

- You have to supply 5V DC power supply to Beaglebone Black or VIBE/VIBE2.

- Note: Before powering up ensure correct software image is loaded in Beaglebone black or VIBE/VIBE2

| Using Beaglebone Black | Using VIBE/VIBE2 |

- For INDU-RS3HD-DC15W

-

- You have two option for supplying power:

- 9V-36V DC power through terminal headers supplied to INDU-RS cape

- You have two option for supplying power:

| Using Beaglebone Black | Using VIBE/VIBE2 |

- 5V DC power through normal adapter supplied to Beaglebone Black or VIBE/VIBE2

Note : For this option, before powering up remove the jumper J1

- 5V DC power through normal adapter supplied to Beaglebone Black or VIBE/VIBE2

| Using Beaglebone Black | Using VIBE/VIBE2 |

Software Setup Guide

In general the RE/DE input requires high level while transmitting data and low level while receiving data. Whereas the standard RTS signal of UART remain low while transmitting data and high while receiving a data. UARTs can be put in RS-485 mode, which will automatically handles RE/DE signal using its RTS pin by using hardware inversion for correcting the default RTS nature. But the built in UARTs of AM335x series lack this hardware inversion capability for generating correct RE/DE signal. So while developing the RS485 application, there was need of software inversion for generating correct RE/DE signal while transmitting and receiving the data.

In INDU-RS3HD and INDU-RS3HD-DC15W capes, Yantrr has added the hardware inversion capability which will generate correct RE/DE signal using default RTS pin in RS-485 mode without any need of software inversion in an application.

For use of INDU-RS3HD and INDU-RS3HD-DC15W, still some basic software setup is required for loading correct 8250 driver and assigning correct RTS pins to UART ports at the runtime using Device Tree configuration.

Software Images

The INDU-RS series capes are tested with latest-release image from beagleboard.org which has inbuilt support for OMAP internal UART (8250 based driver).

Currently INDU-RS485 cape is tested with beaglebone black kernel version 4.4.40-ti-r80.

For Beaglebone Black, we recommend to use latest Debian image from http://beagleboard.org/latest-images/ as it comes with all the necessary support for OMAP internal UART (8250 based driver).

Device Tree Overlays

For particular RS485 port two dtbo files are there

- BB-UART*-00A0.dtbo

- BB-UART*-RTSCTS-00A0.dtbo

Note : * represents the particular port no. of UART used in respective RS485 port. For example, for RS485-Port1 it will be UART4.

The BB-UART*-00A0.dtbo file defines the TX and RX pin configuration of particular UART port. While BB-UART*-RTSCTS-00A0.dtbo file defines the RTS and CTS pin configuration of UART port.

For sending data from any RS485 port, both dtbo files(BB-UART & BB-UART-RTSCTS) of associated UART port should be exported to slots before actual sending of data.

For reading data from any RS485 port, only BB-UART dtbo file is sufficient to get data from associated UART port.

The device tree overlays are compiled as per instructions listed in link https://github.com/RobertCNelson/bb.org-overlays.

Steps:

- Clone the repo

git clone https://github.com/beagleboard/bb.org-overlays cd ./bb.org-overlays

- Verify the dtc version should be latest one

dtc --version Version: DTC 1.4.1-gXYZXYZXYZ

- Upgrade the dtc

./dtc-overlay.sh

- Copy Yantrr-RS485 dts files after extracting ytrDTS.tar.gz file in root directory

cp /root/ytrDTS/src/BB-UART* ./src/arm/

- Install *.dtbo

./install.sh

Note: This will copies all the dtbo files after compilation automatically in directory /lib/firmware/

- capemgr: enable/disable capes on kernel cmdline:

Comma delimited list of PART-NUMBER[:REV] of [enabled/disabled] capes

bone_capemgr.enable_partno=

bone_capemgr.disable_partno= - capemgr: enable/disable capes with slots:

root@beaglebone:~# cat /sys/devices/platform/bone_capemgr/slots 0: PF---- -1 1: PF---- -1 2: PF---- -1 3: PF---- -1

- Add Device :

root@beaglebone:~# sh -c "echo 'BB-UART4' > /sys/devices/platform/bone_capemgr/slots" root@beaglebone:~# cat /sys/devices/platform/bone_capemgr/slots 0: PF---- -1 1: PF---- -1 2: PF---- -1 3: PF---- -1 4: P-O-L- 0 Override Board Name,00A0,Override Manuf,BB-UART4

- Remove Device:

root@beaglebone:~# sh -c "echo '-4' > /sys/devices/platform/bone_capemgr/slots" root@beaglebone:~# cat /sys/devices/platform/bone_capemgr/slots 0: PF---- -1 1: PF---- -1 2: PF---- -1 3: PF---- -1